Precision cutting is crucial for contemporary large-scale infrastructure projects, including skyscrapers and bridges, where accuracy is paramount. Technologies such as Computer Numerical Control (CNC) machining and laser cutting have not only enhanced efficiency but also improved craftsmanship in the construction industry. These innovations minimize errors, control budgets, and reduce material waste, making them fundamental to civil engineering and commercial construction for future growth. The integration of automation and robotics accelerates project timelines, allowing tasks to be completed more swiftly and in compliance with safety standards. Furthermore, precision cutting aligns with sustainability objectives, as it reduces waste and supports environmentally responsible practices. Overall, CNC machining and laser cutting are indispensable for achieving durability and high performance in infrastructure projects.

The Importance of Precision Cutting in Infrastructure

Large-scale infrastructure projects rely heavily on the flawless assembly of countless components. Even minor inaccuracies in fabrication can lead to misaligned joints, material stress points, and eventual structural weaknesses. By incorporating advanced tools and services found at https://bluegrassbit.com/ into the construction process, project leaders can ensure that precision cutting and drilling support the exact fit of steel frames, stone panels, and other essential materials. In turn, this fosters both cosmetic perfection and extended building lifespans. As new construction projects grow more ambitious in scale and design, precision at every level becomes indispensable.

CNC Machining: Enhancing Accuracy and Efficiency

CNC machining utilizes computer-aided design and manufacturing to achieve unmatched levels of accuracy. The process enables the intricate shaping and cutting of construction materials, ranging from metals to advanced composites. Notably, CNC machining is capable of intricate customizations, such as those required in the unique steel and glass structures of the Beijing Daxing International Airport. By leveraging digital plans, builders can replicate complex parts precisely and predictably, ensuring tight tolerances and thus reliable joins every time.

Laser Cutting: Speed and Precision Combined

Laser cutting offers unmatched speed and pinpoint accuracy, making it a go-to solution for fabricating thick, dense materials used in building construction. Technological improvements, including the use of fiber lasers, enable what once took hours to be accomplished in a fraction of the time all while maintaining the highest standards for cut quality. Recent innovations, such as the 60 kW fiber laser system from HSG Laser, have pushed the boundaries of performance and efficiency, enabling clean cuts on materials nearly four inches thick at speeds previously unimaginable.

Material Efficiency and Waste Reduction

By optimizing how each piece is cut and shaped, precision cutting technologies minimize the leftover material often referred to as ‘scrap’ that would otherwise end up as waste. Through advanced programming, manufacturers can nest components to utilize raw materials like steel or aluminum slabs to their fullest potential. This not only curbs project costs but also aligns with green building standards and sustainable construction certification requirements. Particularly on high-budget projects, these savings are multiplied, directly influencing the bottom line.

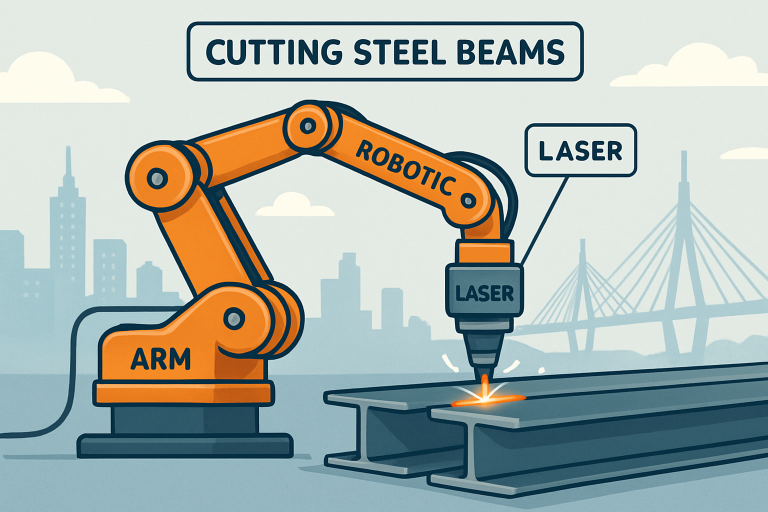

Integration of Robotics and Automation

The evolution of precision cutting is closely tied to the rise of automation and robotics in the construction industry. Robotic arms, for example, can handle repetitive, hazardous, or heavy tasks far more safely and efficiently than human workers. Besides cutting, these machines can also handle precise welding, brick laying, and even large-scale 3D printing of building elements. The result is a standardization of quality, enhanced worker safety, and accelerated construction timelines all made possible by the marriage of robotics and precision machining.

Case Study: The LINE Project

One of the most ambitious infrastructure projects currently underway is Saudi Arabia’s The LINE 170 km linear city housing millions in a narrow urban belt. This endeavor provides a clear example of how advanced precision manufacturing techniques, including robotic construction and digital fabrication, are being leveraged to deliver a project on an unmatched scale with unprecedented precision and sustainability.

Challenges and Future Outlook

Despite their advantages, precision cutting methods come with challenges such as high upfront investment costs and a growing need for technically trained operators. However, advancements in automation, machine learning, and AI-driven monitoring are helping to overcome these concerns, making precision cutting more accessible to firms of all sizes. As the industry continues to evolve, adopting these methods will be crucial for firms aiming to win large contracts and remain ahead of regulatory changes while ensuring the safety and durability of their builds.

Conclusion

The foundation of tomorrow’s infrastructure lies in today’s adoption of precision cutting technologies. Through the integration of CNC machining, laser cutting, robotics, and smart automation, the construction industry is poised for a new era marked by productivity, reliability, and sustainability. As more builders and developers recognize these benefits, precision cutting will only become more central to the global push for innovative, future-ready infrastructure.